SUPAC guidelines are FDA guidelines for Scale-Up and Post-Approval Changes for manufacturing of drugs

Ø SUPAC-IR: Immediate-Release Solid Oral Dosage Forms: Scale-Up and Post-Approval Changes: Chemistry, Manufacturing and Controls, In Vitro Dissolution Testing, and In Vivo Bioequivalence Documentation

Ø SUPAC-MR: Modified Release Solid Oral Dosage Forms Scale-Up and Postapproval Changes: Chemistry, Manufacturing, and Controls; In Vitro Dissolution Testing and In Vivo Bioequivalence Documentation

Ø SUPAC-SS: Nonsterile Semisolid Dosage Forms; Scale-Up and Post-Approval Changes: Chemistry, Manufacturing and Controls; In Vitro Release Testing and In Vivo Bioequivalence Documentation

SUPAC-IR: Immediate-Release Solid Oral Dosage Forms:

Scale-Up and Post-Approval Changes: Chemistry, Manufacturing and Controls, In Vitro Dissolution Testing, and In Vivo Bioequivalence Documentation

I. PURPOSE OF GUIDANCE

This guidance provides recommendations to sponsors of new drug applications (NDA's), abbreviated new drug applications (ANDA's), and abbreviated antibiotic applications (AADA's) who intend, during the postapproval period, to change: 1) the components or composition; 2) the site of manufacture; 3) the scale-up/scale-down of manufacture; and/or 4) the manufacturing (process and equipment) of an immediate release oral formulation. This guidance is the result of: 1) a workshop on the scale-up of immediate release drug products conducted by the American Association of Pharmaceutical Scientists in conjunction with the United States Pharmacopoeial Convention and the Food and Drug Administration (FDA); 2) research conducted by the University of Maryland at Baltimore on the chemistry, manufacturing and controls of immediate release drug products under the FDA/University of Maryland Manufacturing Research Contract; 3) the drug categorization research conducted at the University of Michigan and the University of Uppsala on the permeability of drug substances; and 4) the Scale Up and Post Approval Changes (SUPAC) Task Force which was established by the Center for Drug Evaluation and Research (CDER) Chemistry, Manufacturing and Controls Coordinating Committee to develop guidance on scale-up and other post approval changes.

The guidance defines: 1) levels of change; 2) recommended chemistry, manufacturing, and controls tests for each level of change; 3) in vitro dissolutiontests and/or in vivo bioequivalence tests for each level of change; and 4)documentation that should support the change. For those changes filed in a “changes being effected supplement” [21 CFR 314.70(c)], the FDA may, after a review of the supplemental information, decide that the changes are not

approvable. This guidance thus sets forth application information that should be provided to CDER to assure continuing product quality and performance characteristics of an immediate release solid oral dose formulation for specified postapproval changes. This guidance does not comment on or otherwise affect compliance/inspection documentation that has been defined by CDER’s Office of Compliance or FDA’s Office of Regulatory Affairs. This guidance does not affect any postapproval changes other than the ones specified. For changes not addressed in this guidance, or for multiple changes submitted at one time or over a short period of time, or where the number of batches needed for stability testing is not specified, sponsors should contact the appropriate CDER review division or consult other CDER guidances/guidelines to obtain information about tests and application documentation.

COMPONENTS AND COMPOSITION

This section of the guidance focuses on changes in excipients in the drug product. Changes in the amount of drug substance are not addressed by this guidance. Changes in components or composition that have the effect of adding a new excipient or deleting an excipient are defined at Level 3 (defined below), except as described below.

A. Level 1 Changes

1. Definition of Level:Level 1 changes are those that are unlikely to have any detectable impact on formulation quality and performance.

Examples:

a. Deletion or partial deletion of an ingredient intended to affect the color or flavor of the drug product; or change in the ingredient of the printing ink to another approved ingredient.

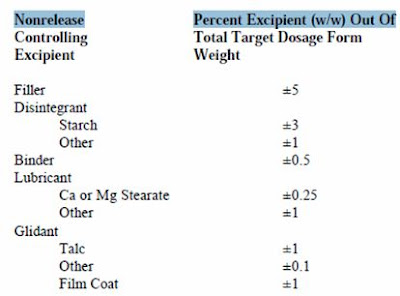

b. Changes in excipients, expressed as percentage (w/w) of total formulation, less than or equal to the following percent ranges:

These percentages are based on the assumption that the drug substance in the product is formulated to 100% of label/potency. The total additive effect of all excipient changes should not be more than 5%. (Example: In a product consisting of active ingredient A, lactose, microcrystalline cellulose and magnesium stearate, the lactose and microcrystalline cellulose should not vary by more than an absolute total of 5% (e.g. lactose increases 2.5% and microcrystalline cellulose decreases by 2.5%) relative to the target dosage form weight if it is to stay within the Level 1 range).

2. Test Documentation

a. Chemistry Documentation:Application/compendial release requirements and stability testing.

Stability testing: one batch on long-term stability data reported in annual report.

b. Dissolution Documentation :None beyond application/compendial requirements.

c. In Vivo Bioequivalence Documentation: None.

3. Filing Documentation:Annual report (all information including long-term stability data).

B. Level 2 Changes

1. Definition of Level:Level 2 changes are those that could have a significant impact on formulation quality and performance. Tests and filing documentation for a Level 2 change vary depending on three factors: therapeutic range, solubility, and permeability.

Therapeutic range is defined as either narrow or non-narrow. A list of narrow therapeutic range drugs is provided in Appendix A. Drug solubility and drug permeability are defined as either low or high. Solubility is calculated based on the minimum concentration of drug, milligram/milliliter (mg/mL), in the largest dosage strength, determined in the physiological pH range (pH 1 to 8) and temperature (37 + 0.5oC). High solubility drugs are those with a dose/solubility volume of less than or equal to 250 mL. (Example: Compound A has as its lowest solubility at 37 + 0.5oC, 1.0 mg/mL at pH 7, and is available in 100 mg, 200 mg and 400 mg strengths. This drug would be considered a low solubility drug as its dose/solubility volume is greater than 250 mL (400 mg/1.0 mg/mL=400 mL). Permeability (Pe, centimeter per second) is defined as the effective human jejunal wall permeability of a drug and includes an apparent resistance to mass transport to the intestinal membrane. High permeability drugs are generally those

with an extent of absorption greater than 90% in the absence of documented instability in the gastrointestinal tract, or those whose permeability attributes have been determined experimentally).

Examples:

a. Change in the technical grade of an excipient. (Example:Avicel PH102 vs. Avicel PH200.)

b. Changes in excipients, expressed as percent (w/w) of total formulation, greater than those listed above for a Level 1 change but less than or equal to the following percent ranges (which represent a two fold increase over Level 1 changes):

These percentages are based on the assumption that the drug substance in the drug product is formulated to 100% of label/potency. The total additive effect of all excipient changes should not change by more than 10%. The components (active and excipients) in the formulation should have numerical targets that represent the nominal composition of the product on which any future changes in the composition of the product are to be based. Allowable changes in the composition should be based on the approved target composition and not on the composition based on previous Level 1 or Level 2 changes.

2. Test Documentation

a. Chemistry Documentation

Application/compendial release requirements and batch records.

Stability testing: 1 batch with 3 months accelerated stability data in supplement and 1 batch on long-term stability.

b. Dissolution Documentation

Case A: High Permeability, High Solubility Drugs Dissolution of 85% in 15 minutes in 900 mL of 0.1N HCl. If a drug product fails to meet this criterion, the applicant should perform the tests described for Case B or C

Case B: Low Permeability, High Solubility Drugs Multi-point dissolution profile should be performed in the application/compendial medium at 15, 30, 45, 60 and 120 minutes or until an asymptote is reached. The dissolution profile of the proposed and currently used product formulations should be similar.

Case C: High Permeability, Low Solubility Drugs Multi-point dissolution profiles should be performed in water, 0.1N HCl, and USP buffer media at pH 4.5, 6.5, and 7.5 (five separate profiles) for the proposed and currently accepted formulations. Adequate sampling should be performed at 15, 30, 45, 60, and 120 minutes until either 90% of drug from the drug product is dissolved or an asymptote is reached. A surfactant may be used, but only with appropriate justification. The dissolution profile of the proposed and currently used product formulations should be similar.

c. In Vivo Bioequivalence Documentation

None: if the situation does not meet the description in Case A, Case B or Case C, refer to Level 3 changes

3. Filing Documentation:Prior approval supplement (all information including accelerated stability data); annual report (long-term stability data).

C. Level 3 Changes

1. Definition of Level:Level 3 changes are those that are likely to have a significant impact on formulation quality and performance. Tests and filing documentation vary depending on the following three factors: therapeutic range, solubility, and permeability.

Examples:

- Any qualitative and quantitative excipient changes to a narrow therapeutic drug beyond the ranges noted in Section III.A.1.b.

- All other drugs not meeting the dissolution criteria under Section III.B.2.b.

- Changes in the excipient ranges of low solubility, low permeability drugs beyond those listed in Section III.A.1.b.

- Changes in the excipient ranges of all drugs beyond those listed in Section III.B.1.b.

2. Test Documentation

a. Chemistry Documentation

Application/compendial release requirements and batch records.

Significant body of information available: One batch with three months accelerated stability data reported in supplement; one batch on long-term stability data reported in annual report.

Significant body of information not available: Up to three batches with three months accelerated stability data reported in supplement; one batch on long-term stability data reported in annual report.

b. Dissolution Documentation

Case B dissolution profile as described in Section III.B.2.b.

c. In Vivo Bioequivalence Documentation:Full bioequivalence study. The bioequivalence study may be waived with an acceptable in vivo/in vitro correlation has been verified.

3. Filing Documentation

Prior approval supplement (all information including accelerated stability data); annual report (long-term stability data).

SITE CHANGES

Site changes consist of changes in location of the site of manufacture for both company-owned and contract manufacturing facilities and do not include any scale-up changes, changes in manufacturing (including process and/or equipment), or changes in components or composition. Scale-up is addressed in Section V of this guidance. New manufacturing locations should have a satisfactory current Good Manufacturing Practice (CGMP) inspection.

A. Level 1 Changes

1. Definition of Level

Level 1 changes consist of site changes within a single facility where the same equipment, standard operating procedures (SOP's), environmental conditions (e.g., temperature and humidity) and controls, and personnel common to both manufacturing sites are used, and where no changes are made to the manufacturing batch records, except for administrative information and the location of the facility. Common is defined as employees already working on the campus who have suitable experience with the manufacturing process.

2. Test Documentation

a. Chemistry Documentation:None beyond application/compendial release requirements.

b. Dissolution Documentation:None beyond application/compendial release requirements.

c. In Vivo Bioequivalence Documentation:None.

3. Filing Documentation:Annual report.

B. Level 2 Changes

1. Definition of Level:Level 2 changes consist of site changes within a contiguous campus, or between facilities in adjacent city blocks, where the same equipment, SOP's, environmental conditions (e.g.,temperature and humidity) and controls, and personnel common to both manufacturing sites are used, and where no changes are made to the manufacturing batch records, except for administrative information and the location of the facility.

2. Test Documentation

a. Chemistry Documentation:Location of new site and updated batch records. None beyond application/compendial release requirements.One batch on long-term stability data reported in annual report.

b. Dissolution Documentation:None beyond application/compendial release requirements.

c. In Vivo Bioequivalence Documentation: None.

3. Filing Documentation:Changes being effected supplement; annual report (longterm stability test data).

C. Level 3 Changes

1. Definition of Level:Level 3 changes consist of a change in manufacturing site to a different campus. A different campus is defined as one that is not on the same original contiguous site or where the facilities are not in adjacent city blocks. To qualify as a Level 3 change, the same equipment, SOP's, environmental conditions, and controls should be used in the manufacturing process at the new site, and no changes may be made to the manufacturing batch records except for administrative information, location and language translation, where needed.

2. Test Documentation:

a. Chemistry Documentation: Location of new site and updated batch records. Application/compendial release requirements.

Stability:

Significant body of data available:One batch with three months accelerated stability data reported in supplement; one batch on long-term stability data reported in annual report.

Significant body of data not available:Up to three batches with three months accelerated stability data reported in supplement; up to three batches on long- term stability data reported in annual report.

b.Dissolution Documentation

Case B: Multi-point dissolution profile should be performed in the application/compendial medium at 15, 30, 45, 60 and 120 minutes or until an asymptote is reached. The dissolution profile of the drug product at the current and proposed site should be similar.

c. In Vivo Bioequivalence Documentation: None.

CHANGES IN BATCH SIZE (SCALE-UP/SCALE-DOWN)

Postapproval changes in the size of a batch from the pivotal/pilot scale biobatch material to larger or smaller production batches call for submission of additional information in the application. Scale-down below 100,000 dosage units is not covered by this guidance. All scale-up changes should be properly validated and, where needed, inspected by appropriate agency personnel.

A.Level 1 Changes

1. Definition of Level:Change in batch size, up to and including a factor of 10 times the size of the pilot/biobatch, where: 1) the equipment used to produce the test batch(es) is of the same design and operating principles;

2) the batch(es) is (are) manufactured in full compliance with CGMP's; and 3) the same standard operating procedures (SOP's) and controls, as well as the same formulation and manufacturing procedures, are used on the test batch(es) and on the full-scale production batch(es).

2. Test Documentation

a. Chemistry Documentation

Application/compendial release requirements. Notification of change and submission of updated batch records in annual report.

One batch on long-term stability reported in annual report.

b. Dissolution Documentation

None beyond application/compendial release requirements.

c. In Vivo Bioequivalence:None.

3. Filing Documentation:Annual report (long-term stability data).

B. Level 2 Changes

1. Definition of Level

Changes in batch size beyond a factor of ten times the size of the pilot/biobatch, where: 1) the equipment used to produce the test batch(es) is of the same design and operating principles; 2) the batch(es) is (are) manufactured in full compliance with CGMP'S; and 3) the same SOP's and controls as well as the same formulation and manufacturing procedures are used on the test batch(es) and on the full-scale production batch(es).

2. Test Documentation

a. Chemistry Documentation:Application/compendial release requirements. Notification

of change and submission of updated batch records.

Stability testing: One batch with three months accelerated

stability data and one batch on long-term stability.

b. Dissolution Documentation: Case B testing.

c. In Vivo Bioequivalence:None.

3. Filing Documentation:Changes being effected supplement; annual report (long-term stability data).

MANUFACTURING

Manufacturing changes may affect both equipment used in the manufacturing process and the process itself.

A. Equipment

1. Level 1 Changes

a. Definition of Change

This category consists of: 1) change from non-automated or non-mechanical equipment to automated or mechanical

equipment to move ingredients; and 2) change to alternative equipment of the same design and operating principles of the same or of a different capacity.

b. Test Documentation

i. Chemistry Documentation:Application/compendial release requirements.

Notification of change and submission of updated batch records.

Stability testing: One batch on long-term stability.

ii. Dissolution Documentation

None beyond application/compendial release requirements.

iii. In Vivo Bioequivalence Documentation

None.

c. Filing Documentation : Annual report (long-term stability data).

2. Level 2 Changes

a. Definition of Level

Change in equipment to a different design and different operating principles.

b. Test Documentation

i. Chemistry Documentation

Application/compendial release requirements.

Notification of change and submission of updated batch records.

Stability testing:

Significant body of data available:One batch with three months accelerated stability data reported in

supplement; one batch on long-term stability data reported in annual report. Significant body of data not available: Up to three batches with three months accelerated stability data reported in supplement; up to three batches on long-term stability data reported in annual report.

ii. Dissolution Documentation:Case C dissolution profile.

iii. In Vivo Bioequivalence Documentation:None.

c. Filing Documentation

Prior approval supplement with justification for change; annual report (long-term stability data).

B. Process

1. Level 1 Changes

a. Definition of Level : This category includes process changes including changes such as mixing times and operating speeds within application/validation ranges.

b. Test Documentation

i. Chemistry Documentation:None beyond application/compendial release requirements.

ii. Dissolution Documentation:None beyond application/compendial release requirements.

iii. In Vivo Bioequivalence Documentation: None.

c. Filing Documentation:Annual report.

2. Level 2 Changes

a. Definition of Level:This category includes process changes including changes such as mixing times and operating speeds outside of application/validation ranges.

b. Test Documentation:

i. Chemistry Documentation

Application/compendial release requirements.

Notification of change and submission of updated batch records.

Stability testing: One batch on long-term stability.

ii. Dissolution Documentation:Case B dissolution profile.

iii. In Vivo Bioequivalence Documentation:None.

c. Filing Documentation:Changes being effected supplement; annual report (longterm stability data).

3. Level 3 Changes

a. Definition of Level:This category includes change in the type of process used in the manufacture of the product, such as a change from wet granulation to direct compression of dry powder.

b. Test Documentation

i. Chemistry Documentation

Application/compendial release requirements. Notification of change and submission of updated batch records.

Stability testing:

Significant body of data available:One batch with three months accelerated stability data reported in supplement; one batch on long-term stability data reported in annual report. Significant body of data not available:

Up to three batches with three months accelerated stability data reported in supplement; up to three batches on long-term stability data reported in annual report.

ii. Dissolution Documentation:Case B dissolution.

iii. In Vivo Bioequivalence Documentation: In vivo bioequivalence study. The bioequivalence study may be waived if a suitable in vivo/in vitro correlation has been verified.

c. Filing Documentation

Prior approval supplement with justification; annual report (long-term stability data).

IN VITRO DISSOLUTION

See current United States Pharmacopeia/National Formulary, section <711>, for general dissolution specifications.

IN VIVO BIOEQUIVALENCE STUDIES

Below is a general outline of an in vivo bioequivalence study. It is intended as a guide and the design of the actual study may vary depending on the drug and dosage form.

A. Objective:

To compare the rate and extent of absorption of the drug product for which the manufacture has been changed, as defined in this guidance, to the drug product manufactured prior to the change.

B. Design:

The study design should be a single dose, two-treatment, two-period crossover with adequate washout period between the two phases of the study. Equal numbers of subjects should be randomly assigned to each

of the two dosing sequences.

C. Selection of Subjects:

The number of subjects enrolled in the bioequivalence study should be determined statistically to account for the intrasubject variability and to meet the current bioequivalence interval.

D. Procedure:

Each subject should receive the following two treatments:

Treatment 1: Product manufactured with the proposed change.

Treatment 2: Product manufactured prior to the proposed change.

Following an overnight fast of at least 10 hours, subjects should receive either Treatments 1 or 2 above with 240 mL water. Food should not be allowed until 4 hours after dosing. Water may be allowed after the first

hour. Subjects should be served standardized meals beginning at 4 hours during the study.

E. Restrictions:

Prior to and during each study phase, water may be allowed ad libitum except for 1 hour before and after drug administration. The subject should be served standardized meals and beverages at specified times.

No alcohol or xanthine- or caffeine-containing foods and beverages should be consumed for 48 hours prior to each study period and until after the last blood sample is collected.

F. Blood Sampling:

Blood samples should be collected in sufficient volume for analysis of parent drug and active metabolite(s), if any. The sampling times should be such that it should be able to capture the Cmax and Tmax during the

absorption period. Sampling should be carried out for at least three terminal elimination half-lives for both parent drug and active metabolite(s). Whole blood, plasma or serum, whichever is appropriate for the analytes, should be harvested promptly and samples should be frozen at -20oC or -70oC to maintain sample stability.

G. Analytical Method:

The assay methodology selected should ensure specificity, accuracy, interday and intraday precision, linearity of standard curves, and adequate sensitivity, recovery, and stability of the samples under the storage and handling conditions associated with the analytical method.

H. Pharmacokinetic Analysis:

From the plasma drug concentration-time data, AUC0-t, AUC0-inf, Cmax, Tmax, Kel and t1/2 should be estimated.

I. Statistical Analysis:

Analysis of variance appropriate for a crossover design on the pharmacokinetic parameters using the general linear models procedures of SAS or an equivalent program should be performed, with examination of period, sequence and treatment effects. The 90% confidence intervals for the estimates of the difference between the test and reference least squares means for the pharmacokinetic parameters (AUC0-t, AUC0-inf, Cmax) should be calculated, using the two one-sided t-test procedure.

SUPAC-MR: Modified Release Solid Oral Dosage Forms

Scale-Up and Postapproval Changes: Chemistry, Manufacturing, and Controls; In Vitro Dissolution Testing and In Vivo Bioequivalence Documentation

GENERAL STABILITY CONSIDERATIONS:

The effect SUPAC-type changes have on the stability of the drug product should be evaluated. For general guidance on conducting stability studies, applicants are referred to the FDA Guideline for Submitting Documentation for the Stability of Human Drugs and Biologics (02/87). For SUPAC submissions, the following points also should be considered:

· In most cases (except those involving scale up), stability data from pilot scale batches will be acceptable to support the proposed change.

· Where stability data show a trend toward potency loss or degradant increase under accelerated conditions, it is recommended that historical accelerated stability data from a representative prechange batch be submitted for comparison. It is also recommended that under these circumstances, all available long-term data on test batches from ongoing studies be provided in the supplement. Submission of historical accelerated and available long-term data would facilitate review and approval of the supplement.

· A commitment should be included to conduct long-term stability studies through the expiration dating period, according to the approved protocol, on the first or first three (see text for details) production batches and to report the results in the annual reports.

COMPONENTS AND COMPOSITION — NONRELEASE CONTROLLING EXCIPIENT

This section of the guidance focuses on changes in nonrelease controlling excipients in the drug product. For modified release solid oral dosage forms, consideration should be given as to whether the excipient is critical or not critical to drug release. The sponsor should provide appropriate justifications for claiming any excipient(s) as a nonrelease controlling excipient in the formulation of the modified release solid oral dosage form. The functionality of each excipient should be identified. Changes in the amount of the drug substance are not addressed by this guidance. Changes in components or composition that have the effect of adding a new excipient or deleting an excipient are defined at level 3 (defined below), except as described below in Section III.A.1.a. Waiver of bioequivalence testing for a change in composition which involves only a different color, flavor or preservative may be permissible as described in 21 CFR 320.22(d)(4).

A)Level 1 Change

Definition of Level:

Level 1 changes are those that are unlikely to have any detectable impact on formulation quality and performance.

Examples:

a. Deletion or partial deletion of an ingredient intended to affect the color or flavor of the drug product; or change in the ingredient of the printing ink to another approved ingredient.

b. Changes in nonrelease controlling excipients, expressed as percentage (w/w) of total formulation, less than or equal to the following percent ranges:

These percentages are based on the assumption that the drug substance in the product is formulated to 100% of label/potency. The total additive effect of all nonrelease controlling excipient changes should not be more than 5%. The total weight of the dosage form should still be within the original approved application range.

The components (active and excipients) in the formulation should have numerical targets that represent the nominal composition of the drug product on which any future changes in the composition of the product are to be based. Allowable changes in the composition should be based on the original approved target composition and not on previous level 1 changes in the composition. For products approved with only a range for excipients, the target value may be assumed to be the midpoint of the original approved application range.

2. Test Documentation

a. Chemistry documentation

Application/compendial product release requirements.

Stability: First production batch on long-term stability data reported in annual report.

b. Dissolution documentation:None beyond application/compendial requirements.

c. Bioequivalence documentation: None.

3. Filing Documentation: Annual report (all information including long-term stability data).

B. Level 2 Change

1)Definition of Level: Level 2 changes are those that could have a significant impact on formulation

quality and performance.

Examples:

a. A change in the technical grade and/or specifications of a nonrelease controlling excipient.

b. Changes in nonrelease controlling excipients, expressed as percentage (w/w) of total formulation, greater than those listed above for a level 1 change, but less than or equal to the following percent ranges (which represent a two-fold increase over level 1 changes):

These percentages are based on the assumption that the drug substance in the drug product is formulated to 100% of label/potency. The total additive effect of all nonrelease controlling excipient changes should not change by more than 10%. The total weight of the dosage form could still be within or outside the original approved application range.

The components (active and excipients) in the formulation should have numerical targets that represent the nominal composition of the product on which any future changes in the composition of the product are to be based. Allowable changes in the composition are based on the original approved target composition and not on the composition based on previous level 1 or level 2 changes. For products approved with only a range for excipients, the target value may be assumed to be the midpoint of the original approved application range.

2)Test documentation

a. Chemistry documentation:

Application/compendial product release requirements and updated executed batch records. Stability: One batch with three months accelerated stability data reported in prior approval supplement and long-term stability data of first production batch reported in annual report.

b. Dissolution documentation:

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification

Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media, in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/

compendial test apparatus (three additional test conditions). If theapplication/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used. Multipoint dissolution profiles should be obtained during the buffer stage of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product).

All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation (6), only application/compendial dissolution testing need be performed (i.e., only in vitro release data by the correlating method need to be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing 2 dissolution profiles . Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate.

c. Bioequivalence documentation: none

3. Filing Documentation: Prior approval supplement (all information including accelerated stability data);

annual report (long-term stability data).

C. Level 3 Change

1. Definition of Level: Level 3 changes are those that are likely to have a significant impact on formulation quality and performance.

Example:Changes in the nonrelease controlling excipient range beyond those listed in Section III.B.1.b. The total weight of the dosage form may be within or outside the approved original application range

2. Test Documentation

a. Chemistry documentation:Application/compendial product release requirements and updated executed batch records.

Stability::Significant body of information available: One batch with three months accelerated stability data reported in prior approval supplement and longterm stability data of first three production batches reported in annual report. Significant body of information not available: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b. Dissolution documentation:

Extended release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained using the application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 1, 2, and 4 hours and every two hours thereafter, until either 80% of the drug from the drug product is released or an asymptote is reached.

Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached.

c. Bioequivalence documentation : A single-dose bioequivalence study . The bioequivalence study may be

waived in the presence of an established in vitro/in vivo correlation.

3. Filing Documentation: Prior approval supplement (all information including accelerated stability data); annual report (long-term stability data).

COMPONENTS AND COMPOSITION — RELEASE CONTROLLING EXCIPIENT

This section of the guidance focuses on changes in release controlling excipients in the drug product. For modified release solid oral dosage forms, consideration should be given as to whether or not the excipient is critical to drug release. The sponsor should provide appropriate justifications (i.e., mechanism of drug release and manufacturing process) for claiming any excipient(s) as a release controlling excipient in the formulation of the modified release solid oral dosage form. The functionality of each excipient should be identified. Changes in the amount of the drug substance are not addressed by this guidance. Changes exceeding the ranges defined in each of the levels below may be allowed if considered to be within normal batch-to-batch variation and contained within an approved original application. In such situations, sponsors should contact the appropriate CDER review division for further guidance.

A) Level 1 Change:

1. Definition of Level: Level 1 changes are those that are unlikely to have any detectable impact on formulation quality and performance.

Example:

a. Changes in the release controlling excipient(s), expressed as percentage (w/w) of total release controlling excipient(s) in the formulation less than or equal to 5% w/w of total release controlling excipient content in the modified release solid oral dosage form.

The drug substance in the product is formulated to 100% of label/potency. The total additive effect of all release controlling excipient changes should not be more than 5% w/w of the total release controlling excipients in the original approved formulation. The total weight of the dosage form should still be within the approved original application range. The components (active and excipients) in the formulation should have numerical targets that represent the nominal composition of the product on which any future changes in the composition of the product are to be based. Allowable changes in the composition should be based on the original approved target composition and not on previous level 1 changes in the composition. For products approved with only a range for excipients, the target value may be assumed to be the midpoint of the original approved application range.

2. Test Documentation

a. Chemistry documentation: Application/compendial product release requirements.

Stability: First production batch on long-term stability data reported in annual report.

b. Dissolution documentation: None beyond application/compendial requirements.

c. Bioequivalence documentation: None.

3. Filing Documentation: Annual report (all information including long-term stability data).

B. Level 2 Change

1. Definition of Level: Level 2 changes are those that could have a significant impact on formulation quality and performance. Test documentation for a level 2 change would vary depending on whether the product could be considered to have a narrow therapeutic range.

Examples:

a. Change in the technical grade and/or specifications of the release controlling excipient(s).

b. Changes in the release controlling excipient(s), expressed as percentage (w/w) of total release controlling excipient(s) in the formulation, greater than those listed above for a level 1 change, but less than or equal to 10% w/w of total release controlling excipient content in the modified release solid oral dosage form.

The drug substance in the drug product is formulated to 100% of label/potency. The total additive effect of all release controlling excipient changes should not be more than 10% w/w of the total release controlling excipient(s) in the original approved formulation. The total weight of the dosage form could still be within or outside the approved original application range.

The components (active and excipients) in the formulation should have numerical targets that represent the nominal composition of the product on which any future changes in the composition of the product are to be based. Allowable changes in the composition are based on the original approved target composition and not on the composition based on previous level 1 or level 2 changes. For products approved with only a range for excipients, the target value may be assumed to be the midpoint of the original approved application range.

2. Test Documentation:

a) Chemistry documentation:Application/compendial product release requirements and updated executed batch records.

Stability:

Nonnarrow therapeutic range drugs: One batch with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first production batch reported in annual report.

Narrow therapeutic range drugs: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b)Dissolution documentation:

Nonnarrow therapeutic range drugs:

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification.

Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/compendial test apparatus (three additional test conditions). If the application/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used. Multipoint dissolution profiles should be obtained during the buffer stage

of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product). All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation, only application/compendial dissolution testing should be performed (i.e., only in vitro release data by the correlating method should be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing dissolution profiles . Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate

Narrow therapeutic range drugs:

Extended release: In addition to application/compendial releaserequirements, a multipoint dissolution profile should be obtained in application/compendial medium for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or

an asymptote is reached. Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial medium for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached

Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial medium for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached.

c. Bioequivalence documentation

Nonnarrow therapeutic range drugs: None.

Narrow therapeutic range drugs: A single-dose bioequivalence study . The bioequivalence study may be waived in the presence of an established in vitro/in vivo correlation . Changes in release controlling excipients in the formulation should be within the range of release controlling excipients of the established correlation.

3. Filing Documentation: Prior approval supplement (all information including accelerated stability data);

annual report (long-term stability data).

C. Level 3 Change

1. Definition of Level: Level 3 changes are those that are likely to have a significant impact on formulation quality and performance affecting all therapeutic ranges of the drug.

Examples:

a. Addition or deletion of release controlling excipient(s) (e.g., release controlling polymer/plasticizer).

b. Changes in the release controlling excipient(s), expressed as percentage (w/w) of total release controlling excipient(s) in the formulation, greater than those listed above for a level 2 change (i.e., greater than 10% w/w of total release controlling excipient content in the modified release solid oral dosage form). Total weight of the dosage form may be within or outside the original approved application range.

2. Test Documentation:

a. Chemistry documentation:

Application/compendial product release requirements and updated executed batch records.

Stability: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b. Dissolution documentation

Extended release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained using application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached.

Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached.

c. Bioequivalence documentation: A single-dose bioequivalence study . The bioequivalence study may be waived in the presence of an established in vitro/in vivo correlation. Changes in release controlling excipients in the formulation should be within the range of release controlling excipients of the established correlation.

3. Filing Documentation: Prior approval supplement (all information including accelerated stability data); annual report (long-term stability data).

V. SITE CHANGES:

Site changes consist of changes in location of the site of manufacture, packaging operations, and/or analytical testing laboratory for both company-owned and contract manufacturing facilities. They do not include any scale-up changes, changes in manufacturing (including process and/or equipment), or changes in components or composition. New manufacturing locations should have had a satisfactory current good manufacturing practice (cGMP) inspection. A stand-alone packaging operations site change, using container(s)/closure(s) in the approved application, may be submitted as a Changes Being Effected supplement. The facility should also have a current and satisfactory cGMP compliance profile with the FDA for the type of packaging operation in question before submitting the supplement. If the facility has not received a satisfactory cGMP inspection for the type of packaging operation in question, a prior approval supplement is recommended. The supplement should contain a written certification from the packaging facility stating that it is in conformance with cGMPs. It should also contain a commitment to place the first production batch of the product, and annual batches thereafter, on long-term stability studies using the approved protocol in the application and to submit the resulting data in annual reports. Where the product is available in more than one strength, size, or container/closure system, one lot of each combination should be placed on long-term stability studies. Bracketing or matrixing is allowed only if it has been approved previously by the FDA. Any changes to an approved stability protocol should have a supplemental approval prior to the initiation of the stability study.

A stand-alone analytical testing laboratory site change may be submitted as a Changes Being Effected supplement if the new facility has a current and satisfactory cGMP compliance profile with the FDA for the type of testing operation in question. The supplement should contain a commitment to use the same test methods employed in the approved application, written certification from the testing laboratory stating that they are in conformance with cGMPs, and a full description of the testing to be performed by the testing lab. If the facility has not received a satisfactory cGMP inspection for the type of testing involved, a prior approval supplement is recommended.

A. Level 1 Change:

1. Definition of Level: Level 1 changes consist of site changes within a single facility where the same equipment, standard operating procedures (SOPs), environmental conditions (e.g., temperature and humidity) and controls, and personnel common7 to both manufacturing sites are used and where no changes are made to the executed batch

records, except for administrative information and the location of the facility.

2. Test Documentation

a. Chemistry documentation: None beyond application/compendial product release requirements.

b. Dissolution documentation:None beyond application/compendial release requirements.

c. Bioequivalence documentation:None.

3. Filing Documentation: Annual report.

B. Level 2 Change:

1.Definition of Level: Level 2 changes consist of site changes within a contiguous campus, or between facilities in adjacent city blocks, where the same equipment, SOPs, environmental conditions

(e.g., temperature and humidity) and controls, and personnel common to both manufacturing sites are used and where no changes are made to the executed batch records, except for administrative information and the location of the facility.

2. Test Documentation

a. Chemistry documentation

Notification of location of new site and updated executed batch records. None beyond application/compendial product release requirements. Stability: One batch with three months accelerated stability data reported in Changes Being Effected supplement and long-term stability data of first production batch reported in annual report.

b. Dissolution documentation

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification. Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media, in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/compendial test apparatus (three additional test conditions). If the application/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used.

Multipoint dissolution profiles should be obtained during the buffer stage of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product). All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation (6), only application/compendial dissolution testing should be performed (i.e., only in vitro release data by the correlating method should be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing 2 dissolution profiles (5). Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate.

c. Bioequivalence documentation: None.

3. Filing Documentation: Changes Being Effected supplement (all information including accelerated stability data); annual report (long-term stability data).

C. Level 3 Change

1. Definition of Level:Level 3 changes consist of a change in manufacturing site to a different campus. A different campus is defined as one that is not on the same original contiguous site or where the facilities are not in adjacent city blocks. To qualify as a level 3 change, the same equipment, SOPs, environmental conditions, and controls should

be used in the manufacturing process at the new site, and no changes may be made to the executed batch records except for administrative information, location and language translation, where needed.

2. Test Documentation

a. Chemistry documentation:Notification of location of new site and updated executed batch records. Application/compendial product release requirements.

Stability:

Significant body of information available: One batch with three months' accelerated stability data reported in prior approval supplement and longterm stability data of first three production batches reported in annual report.

Significant body of information not available: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b. Dissolution documentation:

Extended release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained using application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached.

Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial test conditions for

the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage

form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached.

c. Bioequivalence documentation: A single-dose bioequivalence study (3). The bioequivalence study may be

waived in the presence of an established in vitro/in vivo correlation.

3. Filing Documentation:

Prior approval supplement (all information including accelerated stability test data); annual report (long-term stability data).

VI. CHANGES IN BATCH SIZE (SCALE-UP/SCALE-DOWN)

Postapproval changes in the size of a batch from the pivotal/pilot scale biobatch material to larger or smaller production batches call for submission of additional information to the application. Scale-down below 100,000 dosage units is not covered by this guidance. Adjustments in parameters such as mixing times and speeds may be made to tailor the process to the characteristics of larger or smaller scale equipment. All scale-up changes should be properly validated and, where needed, inspected by appropriate Agency personnel.

A. Level 1 Change

1. Definition of Level

Change in batch size, up to and including a factor of ten times the size of the pilot/biobatch, where (1) the equipment used to produce the test batch(es) may vary in capacity, but are of the same design and operating principles; (2) the

batch(es) is manufactured in full compliance with cGMPs; and (3) the same standard operating procedures (SOPs) and controls, as well as the same formulation and manufacturing procedures, are used on the test batch(es) and on

the full-scale production batch(es).

2. Test Documentation

a. Chemistry documentation: Application/compendial product release requirements. Notification of change and submission of updated executed batch records in annual report.

Stability: First production batch on long-term stability data reported in annual report.

b. Dissolution documentation: None beyond application/compendial release requirements.

c. Bioequivalence documentation: None.

3. Filing Documentation:Annual report (all information including long-term stability data).

B. Level 2 Change

1. Definition of Level:Changes in batch size beyond a factor of ten times the size of the pilot/biobatch where (1) the equipment used to produce the test batch(es) is of the same design and operating principles; (2) the batch(es) is manufactured in full compliance with cGMPs; and (3) the same SOPs and controls as well as the same formulation and manufacturing procedures are used on the test batch(es) and on the full-scale production batch(es).

2. Test Documentation

a. Chemistry documentation

Application/compendial product release requirements. Notification of change and submission of updated batch

records.

Stability: One batch with three months' accelerated stability data reported in Changes Being Effected supplement and long-term stability data of first production batch reported in annual report.

b. Dissolution documentation

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 1, 2, and 4 hours, and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification.

Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/compendial test apparatus (three additional test conditions). If the application/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used.

Multipoint dissolution profiles should be obtained during the buffer stage of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product). All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation (6), only application/compendial dissolution testing should be performed (i.e., only in vitro release data by the correlating method should be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing 2 dissolution profiles (5). Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate.

3. Filing Documentation: sChanges Being Effected supplement (all information including accelerated stability data); annual report (long-term stability data).

VII. MANUFACTURING EQUIPMENT CHANGES

Manufacturing changes may involve the equipment used in the manufacturing process (critical manufacturing variable). If a manufacturer wishes to use manufacturing equipment that is not identical in every respect to the original manufacturing equipment used in the approved application, appropriate validation studies should be conducted to demonstrate that the new equipment is similar to the original equipment. For modified release solid oral dosage forms, consideration should be given as to whether or not the change in manufacturing equipment is

critical to drug release (critical equipment variable).

A. Level 1 Change:

1. Definition of Level:

This category consists of (1) change from nonautomated or nonmechanical equipment to automated or mechanical equipment to move ingredients and (2) change to alternative equipment of the same design and operating principles of the same or of a different capacity.

2. Test documentation

a. Chemistry documentation

Application/compendial product release requirements. Notification of change and submission of updated executed batch records.

Stability: First production batch on long-term stability data reported in annual report.

b. Dissolution documentation: None beyond application/compendial release requirements.

c. Bioequivalence documentation: None.

3. Filing Documentation

Annual report (all information including long-term stability data).

B. Level 2 Change

1. Definition of Level: Change in equipment to a different design and different operating principles.

2. Test Documentation:

a. Chemistry documentation

Application/compendial product release requirements. Notification of change and submission of updated executed batch records.

Stability:

Significant body of information available: One batch with three months' accelerated stability data reported in prior approval supplement and longterm stability data of first three production batches reported in annual report.

Significant body of information not available: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b. Dissolution documentation

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example, at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification.

Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media, in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/compendial test apparatus (three additional test conditions). If the application/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used. Multipoint dissolution profiles should be obtained during the buffer stage of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product).

All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation (6), only application/compendial dissolution testing should be performed (i.e., only in vitro release data by the correlating method should be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing 2 dissolution profiles (5). Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate.

c. Bioequivalence documentation: None.

3. Filing Documentation: Prior approval supplement with justification for change (all information including accelerated stability data); annual report (long-term stability data).

VIII. MANUFACTURING PROCESS CHANGES

Manufacturing changes may involve the manufacturing process itself (critical manufacturing variable). If a manufacturer wishes to use a manufacturing process that is not identical in every respect to the original manufacturing process used in the approved application, appropriate validation studies should be conducted to demonstrate that the new process is similar to the original process. For modified release solid oral dosage forms, consideration should be given as to whether or not the change in manufacturing process is critical to drug release (critical processing variable). For purposes of categorizing the level of changes, process change may be considered only to affect a release controlling excipient when both types of excipients (i.e.,nonrelease and release controlling) are present during the unit operation undergoing a change.

A. Level 1 Change

1. Definition of Level: Process changes involving adjustment of equipment operating conditions such as mixing times and operating speeds within original approved application ranges affecting the nonrelease controlling and/or release controlling excipient(s). The sponsor should provide appropriate justifications for claiming any excipient(s) as a nonrelease controlling or a release controlling excipient in the formulation of the modified release solid oral dosage form.

2. Test Documentation

a. Chemistry documentation:None beyond application/compendial product release requirements. Notification of the change and submission of the updated executed batch records.

b. Dissolution documentation:None beyond application/compendial release requirements.

c. Bioequivalence documentation:None.

3. Filing Documentation: Annual report.

B. Level 2 Change

1. Definition of Level

This category includes process changes involving adjustment of equipment operating conditions such as mixing times and operating speeds outside of original approved application ranges.

2. Test Documentation

a. Chemistry documentation

Application/compendial product release requirements. Notification of change and submission of updated executed batch records.

Stability: One batch with three months' accelerated stability data reported in Changes Being Effected supplement and long-term stability data of first production batch reported in annual report.

b. Dissolution documentation

Extended release: In addition to application/compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1N HCl, and USP buffer media at pH 4.5, and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached. A surfactant may be used with appropriate justification. Delayed release: In addition to application/compendial release requirements, dissolution tests should be performed in 0.1 N HCl for 2 hours (acid stage) followed by testing in USP buffer media, in the range of pH 4.5-7.5 (buffer stage) under standard (application/compendial) test conditions and two additional agitation speeds using the application/

compendial test apparatus (three additional test conditions). If the application/compendial test apparatus is the rotating basket method (Apparatus 1), a rotation speed of 50, 100, and 150 rpm may be used, and if the application/compendial test apparatus is the rotating paddle method (Apparatus 2), a rotation speed of 50, 75, and 100 rpm may be used. Multipoint dissolution profiles should be obtained during the buffer stage of testing. Adequate sampling should be performed, for example, at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached. The above dissolution testing should be performed using the changed drug product and the biobatch or marketed batch (unchanged drug product).

All modified release solid oral dosage forms: In the presence of an established in vitro/in vivo correlation (6), only application/compendial dissolution testing should be performed (i.e., only in vitro release data by the correlating method should be submitted). The dissolution profiles of the changed drug product and the biobatch or marketed batch (unchanged drug product) should be similar. The sponsor should apply appropriate statistical testing with justifications (e.g., the f equation) for comparing 2 dissolution profiles (5). Similarity testing for the two dissolution profiles (i.e., for the unchanged drug product and the changed drug product) obtained in each individual medium is appropriate.

c. Bioequivalence documentation: None.

3. Filing Documentation: Changes Being Effected supplement (all information including accelerated stability

data); annual report (long-term stability data).

C. Level 3 Change

1. Definition of Level:This category includes change in the type of process used in the manufacture of the product, such as a change from wet granulation to direct compression of dry powder.

2. Test Documentation

a. Chemistry documentation

Application/compendial product release requirements. Notification of change and submission of updated executed batch records.

Stability: Three batches with three months' accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report.

b. Dissolution documentation:

Extended release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained using application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 1, 2, and 4 hours and every two hours thereafter until either 80% of the drug from the drug product is released or an asymptote is reached.

Delayed release: In addition to application/compendial release requirements, a multipoint dissolution profile should be obtained during the buffer stage of testing using the application/compendial test conditions for the changed drug product and the biobatch or marketed batch (unchanged drug product). Adequate sampling should be performed, for example at 15, 30, 45, 60, and 120 minutes (following the time from which the dosage form is placed in the buffer) until either 80% of the drug from the drug product is released or an asymptote is reached.

c. Bioequivalence documentation

A single-dose bioequivalence study. The bioequivalence study may be waived in the presence of an established in vitro/in vivo correlation .

3. Filing Documentation:Prior approval supplement (all information including accelerated stability data); annual report (long-term stability data).

SUPAC-SS Nonsterile Semisolid Dosage Forms:

Chemistry, Manufacturing, and Controls; In Vitro Release Testing and In Vivo Bioequivalence Documentation

I. INTRODUCTION

This guidance provides recommendations to pharmaceutical sponsors of new drug applications (NDAs), abbreviated new drug applications (ANDAs), and abbreviated antibiotic drug applications (AADAs) who intend to change (1) the components or composition, (2) the manufacturing (process and equipment), (3) the scale-up/scale-down of manufacture, and/or (4)the site of manufacture of a semisolid formulation during the postapproval period. This guidance addresses nonsterile semisolid preparations (e.g., creams, gels, lotions, and ointments) intended for topical routes of administration. The guidance defines (1) the levels of change; (2) recommended chemistry, manufacturing, and controls (CMC) tests to support each level of change; (3) recommended in vitro release tests and/or in vivo bioequivalence tests to support each level of change; and (4) documentation to support the change.

The guidance specifies the application information that should be provided to the Center for Drug Evaluation and Research (CDER) to ensure continuing product quality and performance chacteristics of the semisolid topical formulation for specified changes. The guidance does not comment on or otherwise affect compliance/inspection documentation defined by the Office of Compliance in CDER or the Office of Regulatory Affairs at FDA.

II. GENERAL BACKGROUND

In general, semisolid dosage forms are complex formulations having complex structural elements. Often they are composed of two phases (oil and water), one of which is a continuous (external) phase, and the other of which is a dispersed (internal) phase. The active ingredient is often dissolved in one phase, although occasionally the drug is not fully soluble in the system and is dispersed in one or both phases, thus creating a three-phase system. The physical properties of the dosage form depend upon various factors, including the size of the dispersed particles, the interfacial tension between the phases, the partition coefficient of the active ingredient between the phases, and the product rheology. These factors combine to determine the release characteristics of the drug, as well as other characteristics, such as viscosity.

A. Critical Manufacturing Parameters: